Polydicyclopentadiene Modified Polyester

Properties and Applications

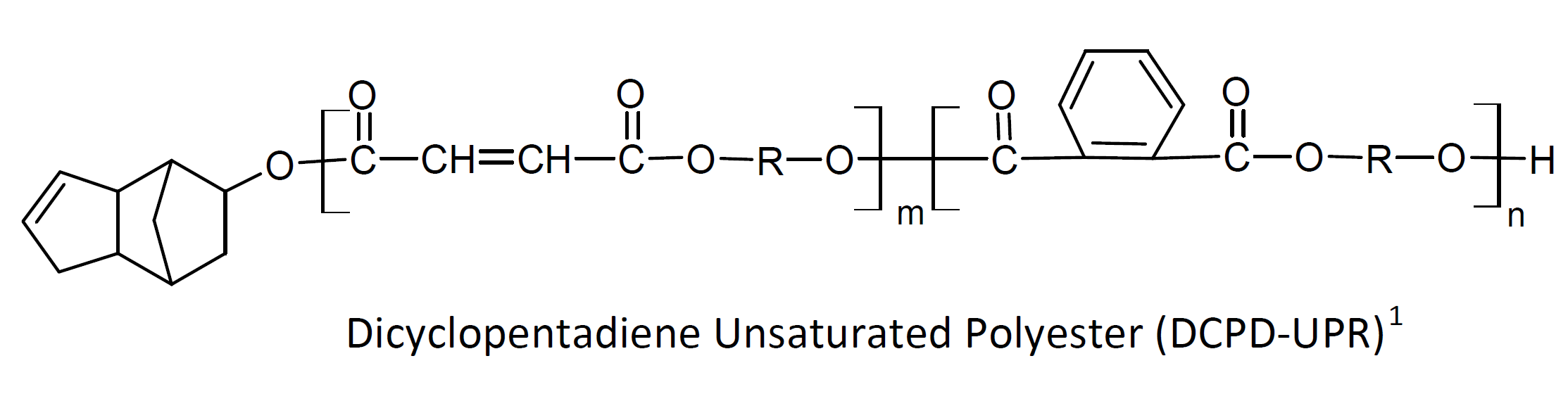

Dicyclopentadiene unsaturated polyesters resins are inexpensive thermosetting resins which are synthesized from dicyclopentadiene, maleic anhydride, and a glycol.2,3 They are typically dissolved in a vinyl monomer (and occasionally a solvent) together with an appropriate organic peroxide and converted into a thermoset by heating.

These resins have gained significant market share due to their low shrinkage and low styrene content. They also provide enhanced thermo-oxidative resistance, improved processability and lower linear shrinkage when compared with traditional unsaturated polyesters.

DCPD modified polyester resins are particularly suited for the manufacture of large glass fiber reinforced plastic articles including sanitary-ware, tanks, pipes, gratings, and high performance components for the marine and transportation industry such as closure panels, body panels, fenders, boat hulls and decks. They also find uses in coatings and adhesives.